Modern Methods of Construction (MMC)

For regular readers of our blog, you will know that we regularly discuss MMC and its many benefits to the construction industry.

In this blog, we’re going to delve a little deeper into just what MMC is, looking into some key elements that fall under this category.

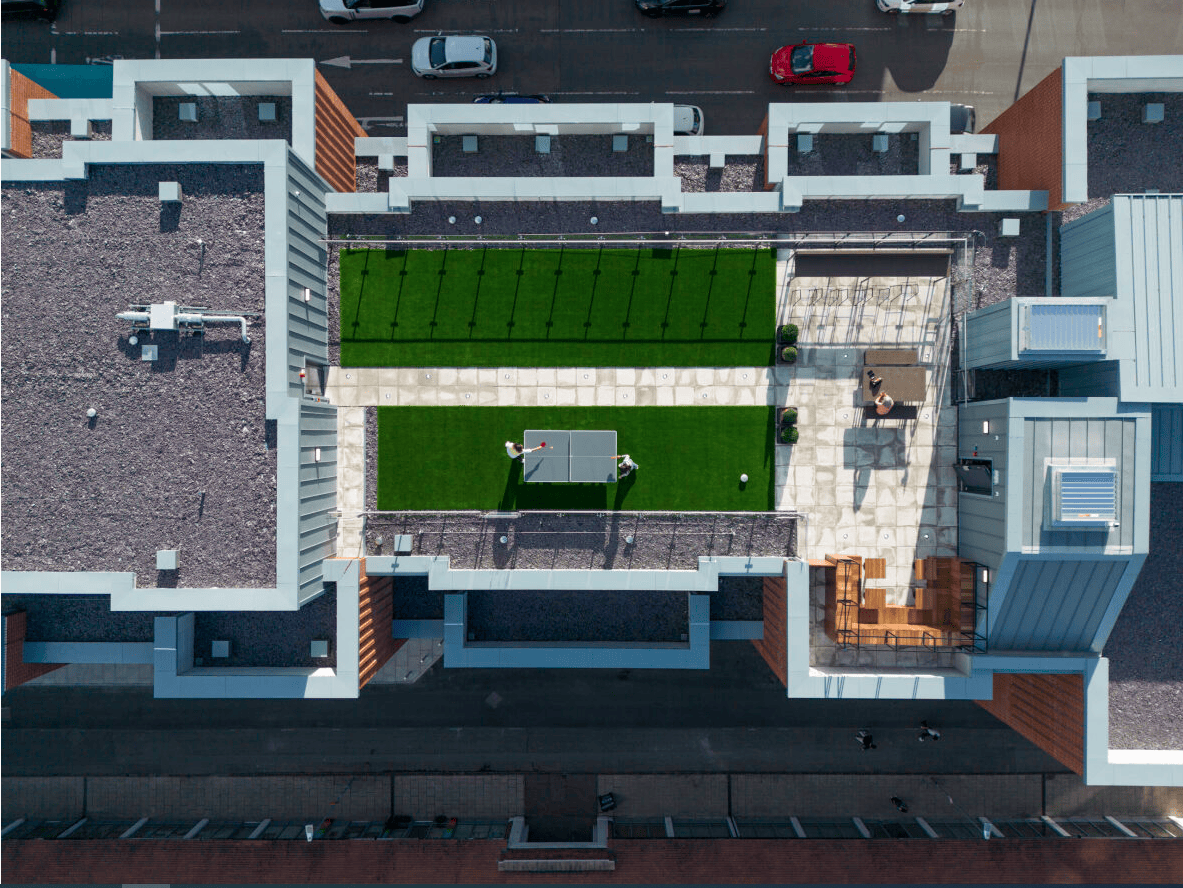

Here at Studio Anyo, we’re passionate about innovation and efficiency in construction, and many of the methods and techniques about to be mentioned are being adopted in our projects throughout the UK and beyond.

From modular marvels to digital design, we will guide you through these innovative new practices.

Let’s take a look.

Modular Construction

This is very much at the heart of MMC and is a key factor in increasing the efficiency of these builds.

In the world of modular construction, we see a future of limitless possibilities.

It’s all about constructing modules in a factory setting and assembling them on-site. This approach not only speeds up construction but also reduces waste significantly.

At Studio Anyo, we’ve seen first-hand how modular methods can transform projects, offering unparalleled precision and quality, and as the technology grows, the speed and accuracy with which components can be made and transported is only going to improve.

Volumetric Construction

Think of volumetric construction as building with giant Lego blocks.

These pre-built volumetric units are stacked and joined to create entire structures. This is a subset of modular construction but differs slightly as the units created are often larger and more complex in terms of design.

Efficiency, quality control, and reduced site disruption are just some of the benefits.

We’ve leveraged this technique in multiple projects, witnessing its potential to cut construction times drastically.

Precast Concrete

In the world of MMC and construction as a whole, precast concrete is a game-changer.

Fabricated off-site under controlled conditions, these concrete elements are then transported and assembled on-site.

The beauty lies in its consistency and quality. It’s a cornerstone in our design philosophy, providing strength and durability to our structures.

Flat Slab Construction

The simplicity of flat slab construction, with its minimal beams and sleek finish, aligns perfectly with our aesthetic ethos at Studio Anyo.

This is sticking to the topic of concrete and is the process of adding a reinforced concrete slab to a project. This is supported by concrete columns and therefore doesn’t need beams or girders for support.

This method not only allows for versatile layouts but also facilitates easier installation of services.

It’s a testament to our commitment to functional, yet stylish design.

Precast Panels

Precast panels epitomise modern construction aesthetics.

They are similar to the precast concrete mentioned above but differ slightly in their application. Whereas precast panels refer to all concrete elements, panels are a sub-set of that and refer to only flat, panel-like structures.

They’re versatile, energy-efficient, and can be visually stunning.

Our journey with precast panels has taught us the value of balance – between form and function, aesthetics and sustainability.

Insulating Concrete Formwork

In our quest for sustainability, insulating concrete formwork has been a revelation.

This method involves concrete poured into insulated forms, providing excellent thermal and acoustic insulation.

It’s a step towards our goal of creating more energy-efficient buildings, and every project that this technique is used on can boast great insulation, which means less energy is used to keep the temperature at a comfortable level.

Thin Joint Masonry

The elegance of thin joint masonry lies in its simplicity and efficiency.

The process involves using thin layers of mortar, rather than the more traditional 10mm joints.

These thinner joints mean that laying rates can be quicker and thermal performance is increased due to their being fewer gaps.

It speeds up the construction process, and at Studio Anyo, we’ve found it incredibly effective for projects with tight timelines.

Twin Wall Technology

Twin wall technology, a method involving two concrete layers with a cavity in between, has been a focal point in some of our innovative projects.

This method, where the gap in the walls is later filled with concrete on site, combines the strength of concrete with the speed and precision of precast techniques.

It’s not just structurally sound but also offers excellent insulation properties.

Digital Construction

With every passing year, the world seems to get more digital, and construction is no different.

Embracing digital construction has been a transformative journey for us.

Using digital tools, such as our very own Strukturera, we can streamline the design and construction process, enhancing precision and reducing errors.

Some popular digital techniques that are being incorporated into construction are Building Information Modelling (BIM), 3D printing to rapidly produce modules and components, and various ways AI can be used to speed up processes.

It’s a glimpse into the future of construction and one that we find really exciting.

MMC at Studio Anyo

At Studio Anyo, we believe in pushing boundaries and exploring new horizons in construction.

Each element of MMC offers unique advantages and opportunities for innovation. As we continue to design and build, we’re excited to integrate these methods into our projects, shaping a more efficient, sustainable, and aesthetically pleasing built environment.

We hope this blog has helped shed light on just what is involved in MMC and provide a bit of insight into what we do on our projects.

If you would like to see what we can do to help your project, then get in touch with our team today, or why not check out our MMC webinars and podcasts?