THE DESIGN PROCESS

The main difference with MMC is the early design freeze and a much higher level of design coordination. The design is taken to the production stage, which creates a design fix much earlier in the process. The risk is that any design changes made later in the project can have cost implications. When the design needs design development, the process of using a prototype is ideal as a full sized room can be manufactured and signed off.

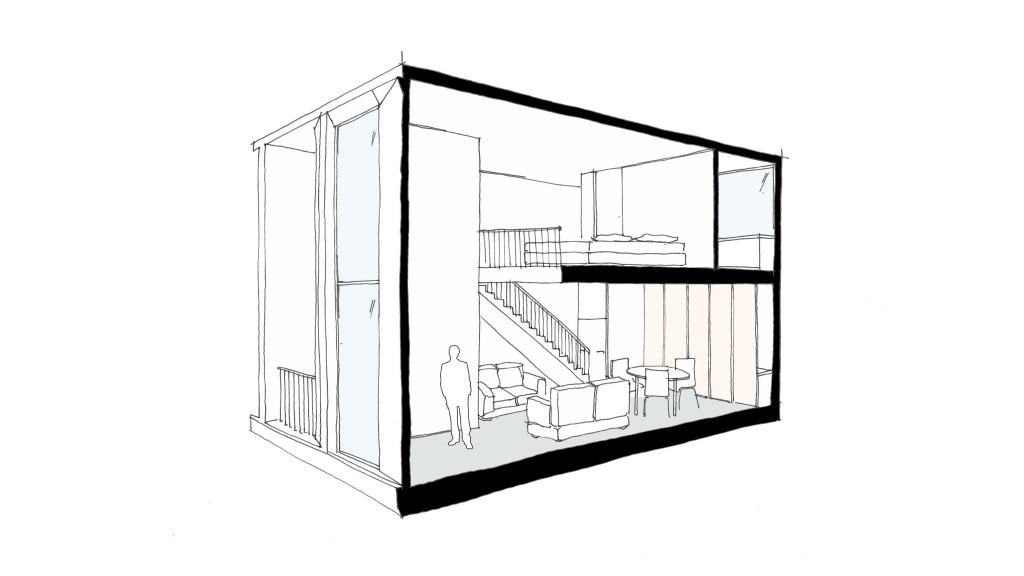

ARCHITECTURAL DESIGN

Modular systems are made up of a series of modularised steel frames, which are manufactured off-site to a high level of dimensional tolerance. For fire protection, acoustics and the prevention of disproportionate collapse, the steel framed modules perform the same as any traditionally constructed building with a steel frame. While making use of bearing wall panels, additional columns and beams frame the space between rooms, the window openings and also support the heavy roof mounted structure and plant items.

STRUCTURAL DESIGN

When two or more modules are placed next to each other they can be designed with open sides to make larger open spaces. Designs can also include knock-out-panels in the module bearing walls so smaller rooms can be expanded to suit the changing needs of the space. Modules will also work alongside traditional construction either below or above the modular components, as loads will be transferred through the bearing walls and isolated columns down to the foundations, which means roof terraces, bars, offices and plant rooms can all be included. When it comes to tolerances, factory-controlled fabrication allows complex interior fit outs to be mass produced, and those buildings with intricate façades can be constructed to a high level of accuracy through the pre-installation of glazing and cladding elements.

FACTORY SYSTEM

Traditionally, with an on-site installation of MEP services, there’s a big reliance on a large number of trades working together in confined spaces, which needs complex project management, sequencing and intense programme input. With a modular construction these issues are avoided entirely. Modular systems can give you a complete interior solution for hotels, resorts, restaurants, apartments, and student accommodation, alongside furniture for the retail market too. Modular construction is a realistic and affordable option and a viable alternative to a labour-intensive, time-consuming on-site production and assembly.

Work With Us

Looking to get started?

Get in touch with Studio Anyo today to speak to one of our in-house experts